No products in the cart.

Uncategorized

Pneumatic Air Mixers: The Best Choice for Safe and Reliable Mixing in Hazardous Environments

When working in hazardous environments, safety isn’t an option—it’s a requirement. Whether dealing with volatile chemicals, combustible solvents, or flammable gases, industries such as chemical engineering, laboratories, and cosmetic labs need a mixing solution that minimizes risk. Pneumatic air mixers stand out as the best option for professionals needing reliable, explosion-proof performance. These mixers offer durability, efficiency, and safety in environments where traditional electric mixers could pose a serious hazard.

What Are Pneumatic Air Mixers?

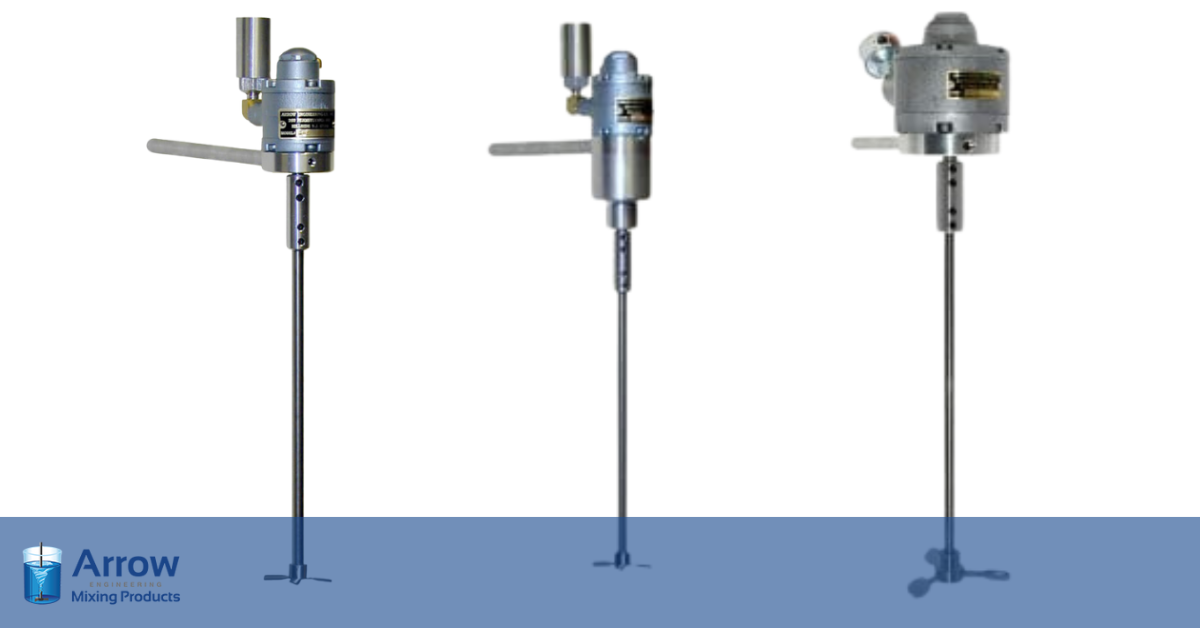

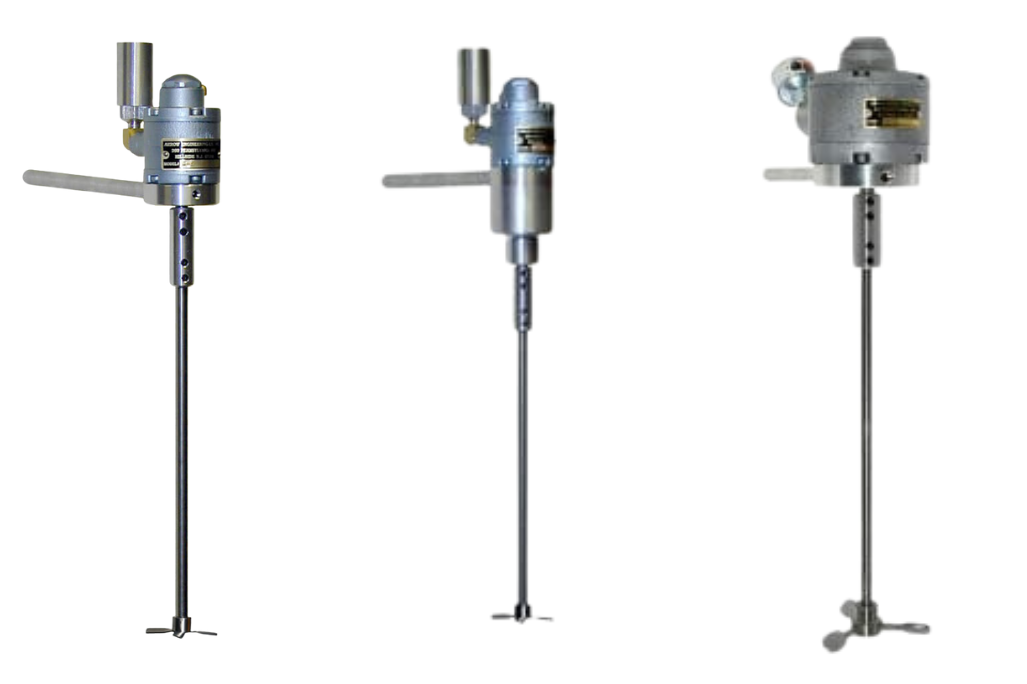

Pneumatic air mixers use compressed air to generate rotational force, eliminating the need for electricity. This design makes them ideal for hazardous locations where sparks could ignite flammable materials. Instead of relying on motors with electrical currents, these mixers harness air power to achieve high-speed, consistent mixing.

At Arrow Mixing Products, we provide industrial-grade air mixers engineered for professionals working with volatile substances. Our products are designed for precision, durability, and compliance with strict safety regulations.

Key Advantages of Pneumatic Air Mixers

Choosing the right mixer for hazardous applications requires an understanding of safety, efficiency, and long-term reliability. Here’s why pneumatic air mixers are the preferred solution in industrial settings:

1. Explosion-Proof Operation

Unlike electric mixers, air mixers do not generate sparks or heat, making them inherently explosion-proof. This critical feature ensures safe operation in chemical plants, R&D laboratories, and industrial settings handling highly combustible liquids.

2. Reliable and Consistent Performance

Pneumatic air mixers deliver high torque and adjustable speed control, ensuring optimal performance for various mixing applications. Whether working with high-viscosity resins, solvents, or corrosive chemicals, air-powered mixers maintain steady operation without overheating or experiencing motor burnout.

Arrow offers both reversible and non-reversible air mixers capable of handling high-speed, high-torque mixing applications. Each overhead stirrer comes equipped with a needle valve to control mixing speed, providing precision and flexibility for demanding tasks.

3. Minimal Maintenance and Longevity

With fewer moving parts than electric alternatives, air mixers experience less wear and tear. This translates to lower maintenance costs, fewer breakdowns, and longer operational life. Since they don’t rely on electrical components, they also withstand exposure to dust, moisture, and chemical vapors without suffering internal damage.

For the best results and extended mixer life, we recommend using a filter/regulator in the air supply and an air-line lubricator to keep the motor running smoothly.

4. Versatility Across Applications

From cosmetic formulation to chemical blending and industrial coatings, pneumatic air mixers accommodate a wide range of mixing needs. Adjustable speed and interchangeable impeller designs allow professionals to customize mixing power and flow based on the specific requirements of their applications.

Each explosion-proof air-driven mixer comes standard with:

- An aluminum support rod

- A four-foot air hose

- A 316 stainless steel shaft and propeller

Built for reliability and ideal performance, these mixers ensure consistent results in demanding applications and are designed to meet the rigorous demands of various industries.

5. Fast and Easy Installation

Arrow’s pneumatic air mixers are designed for quick setup and seamless integration into existing systems. With lightweight and portable designs, these mixers can be easily moved between workstations or installed on tanks, drums, or totes.

Choosing the Right Air Mixer for Your Needs

Selecting the right air mixer depends on several factors, including:

- Tank size and material – Ensure compatibility with drum or tote dimensions.

- Viscosity of materials – Different impellers and speeds accommodate varying viscosities.

- Mixing speed requirements – Adjustable controls allow for customized performance.

- Regulatory compliance – Our mixers meet industry safety standards for hazardous environments.

Arrow Mixing Products provides expert guidance to help professionals choose the best air mixer for their application. With decades of industry experience, our team ensures you get a reliable, high-performance solution tailored to your needs.

Why Arrow Mixing Products?

With a legacy dating back to 1945, Arrow Mixing Products has been a trusted name in industrial mixing solutions. Our pneumatic air mixers are hand-assembled, rigorously tested, and backed by a 30-day satisfaction guarantee. Additional benefits of choosing Arrow include:

- 1-year warranty on all mixers

- Repair service available for minimal downtime

- Repair parts at cost only, ensuring affordability

- Fast, 1-2 business day service with shipping available nationwide and internationally

- Competitive pricing without compromising quality

Get the Best Mixing Solution for Hazardous Environments

If safety, reliability, and efficiency are top priorities for your mixing applications, pneumatic air mixers are the best choice. Arrow Mixing Products offers top-tier air mixers designed to meet the toughest industrial demands. Contact us today to learn more about our available air-powered stirrers or explore our selection of pneumatic air mixers and experience the Arrow difference.