No products in the cart.

Uncategorized

From Labs to Large-Scale Manufacturing: How Arrow Mixers Deliver Consistent Results

Consistent and repeatable results are critical in chemical engineering, cosmetics production, and laboratory testing. Whether mixing delicate formulations or processing high-viscosity compounds, precision at every stage determines product quality and project success. That’s why professionals turn to Arrow Mixing Products, a trusted manufacturer of industrial mixers designed for applications that require accuracy, reliability, and safety.

From benchtop experiments to large-scale manufacturing, Arrow’s electric and pneumatic mixers offer the performance to control every variable.

Built for Industrial Applications—Not Repurposed Food Equipment

Arrow Mixing Products focuses exclusively on serving industries like chemical engineering, cosmetics, pharmaceuticals, and coatings, where product quality depends on proper mixing. Unlike generalized or repurposed mixers, Arrow’s lineup is purpose-built for industrial applications.

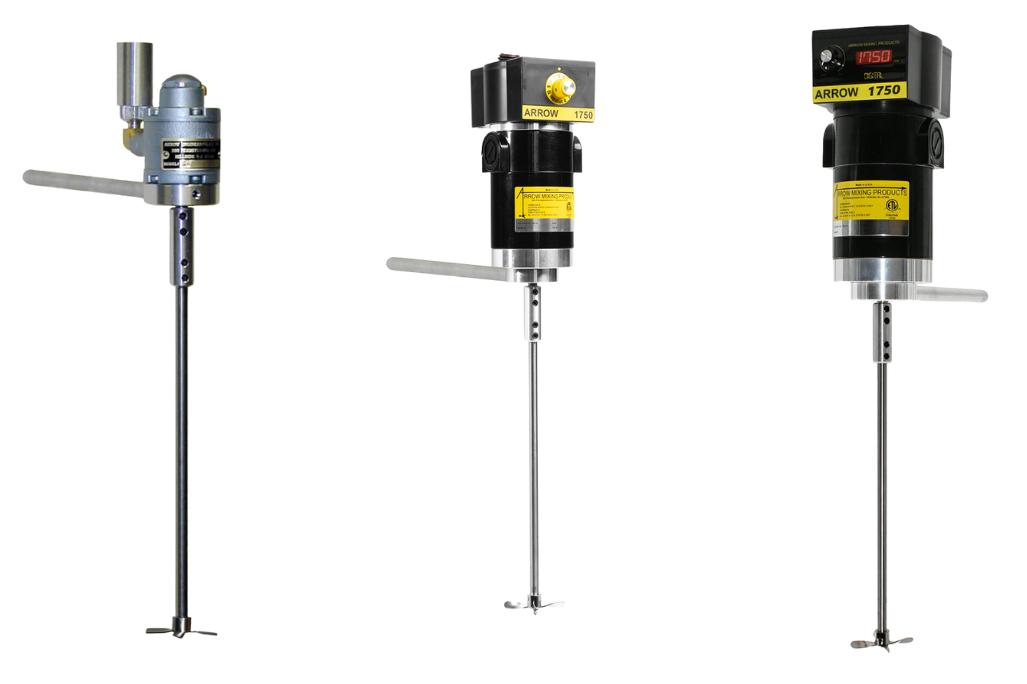

With various models, users can select mixers that handle everything from thin liquids to heavy, viscous compounds. Pneumatic air mixers excel in hazardous environments, while electric models tackle lab work and production with adjustable speeds.

Every item is designed to handle the industry’s demands, giving users confidence that their mixer is up to the task.

Seamless Scaling from Lab to Production

Scaling a formula from lab testing to manufacturing often causes inconsistencies. What blends perfectly in a 1-liter beaker may fail in a 100-gallon tank. Arrow solves this problem by offering mixer models for small-scale R&D and large production batches.

Our electric mixers offer fine-tuned control for lab testing, while air mixers with longer shafts and heavy-duty impellers tackle large drums or tanks. This consistent equipment line ensures that shear, speed, and other mixing variables remain constant, no matter the scale.

Engineers and lab managers can view Arrow’s product range and find mixers that maintain batch-to-batch consistency as operations grow.

The Advantage of Digital Display Readouts—Accuracy at a Glance

One standout feature in Arrow’s digital electric mixer line is the inclusion of digital display readouts, which transform precision and productivity in industrial mixing.

- Accuracy with Mixer Speed: Revolutionizing Precision

Traditional mixers rely on guesswork—set the dial and hope for the best. But in industrial applications, every RPM matters. Arrow’s digital mixers allow users to check and set exact RPMs, eliminating uncertainty. Whether dispersing pigments or controlling shear rates, users achieve precise speed settings that ensure consistent and reproducible results, batch after batch.

- Certainty in Experiments: Eliminating Guesswork

Arrow’s digital readouts provide immediate feedback on mixer speed, giving researchers and production teams confidence in their processes. There’s no second-guessing or repeated trial and error—just clear, real-time data supporting controlled experimentation and reliable scale-up.

- Streamlined Workflow Efficiency: Enhancing Productivity

Manual adjustments and rechecks waste time. Digital displays streamline workflows by allowing operators to view quickly and set speeds, saving valuable time on every run. This efficiency translates to increased throughput and fewer process delays from lab trials to production.

- Unparalleled Precision and Consistency: Setting New Standards

Arrow’s digital mixers help achieve unmatched consistency across multiple production runs. Uniform formulations, reduced waste, and higher-quality end products become the standard—not the exception.

- Reliability: Trusting in Superior Performance

Arrow’s digital mixers are engineered for durability. Operators in chemical plants, cosmetic labs, and other industrial settings can trust these mixers to perform reliably under demanding conditions—day after day.

Safety-First Solutions for Hazardous Environments

Safety cannot be compromised in environments where flammable or reactive materials are mixed. Arrow’s pneumatic mixers provide a reliable, spark-free solution designed for hazardous locations.

Powered by compressed air, these mixers eliminate the ignition risks of electric motors, making them ideal for handling volatile solvents, coatings, and chemicals. With durable construction and corrosion-resistant materials, Arrow’s air mixers protect both the product and the operators.

Durable, Low-Maintenance Design for Heavy Use

Arrow mixers are built to endure the realities of industrial use. Constructed from robust materials and featuring direct-drive motors and sealed bearings, these mixers minimize wear and maintenance.

Whether working with caustic chemicals or abrasive compounds, Arrow’s equipment maintains performance without frequent repairs or replacements—keeping production lines running smoothly.

Mixers and Accessories to Fit Every Task

Arrow Mixing Products offers various mixer models and accessories to support unique application needs. Customers can customize their setups from multiple shaft lengths, propeller types, clamps, and stands.

From lightweight benchtop models to heavy-duty air mixers designed for drum mounting, Arrow ensures that every application is covered. Users can quickly check and view items online to build the perfect mixing system for their process.

Consistency, Precision, and Safety—Find the Right Mixer with Arrow

In industries where mixing precision defines product quality, Arrow Mixing Products delivers mixers built to handle the job—a sensitive lab trial or a large production run. With digital electric mixers offering exact RPM control and pneumatic air mixers designed for safety, Arrow covers every application with unmatched reliability. Ready to explore Arrow’s complete product lineup? Check out the full range of items today at Arrow Mixing Products, or contact us today to discover how the right mixer can improve consistency, safety, and productivity, batch after batch.